Warehousing

Save the warehouse cost Packaging materials can take up a lot of storage space and keeping packaging in stock involves various costs. This is why

Boxon provided export packaging solutions for a well-known power generation equipment company.

A well-known power generation equipment company

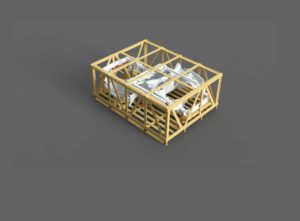

Large power generation equipment

A well-known power generation equipment company would deliver the first batch of equipment for their major international customer, and the equipment needed to be exported to the United States.

The equipment is large and heavy. The heaviest one weighs 42 tons. They would be transported by land, sea and land to the destination. During the transportation, it would experience damp, bumpy and other logistics environment challenges. Besides, the delivery was very urgent. The client had booked the shipping and the equipment would be exported in half a month.

At that time, the power generation equipment was not yet fully finished. Therefore we developed the packaging solution based on the equipment drawings and comprehensive analysis of the logistics environment. Considering the tight delivery, we held quite some meetings with the relevant departments of the client to discuss the packaging solution, and work overtime to optimize the solution to ensure the smooth implementation of the project.

The packaging mainly included solid wood pallets, shrink wrap and rain-proof cloth. The shrink wrap and the desiccant could make the goods in a dry state to resist the humid environment during shipping. And the rainproof cloth could prevent rain and dust from the equipment. In addition, we added protection at critical points of the equipment, including using cushioning materials to prevent collision damage and anti-rust paper to prevent corrosion. Moreover, the operation convenience had also been considered so that the handling through the logistics could be much easier.

We also provided on-site packaging services for the project. Boxon’s packaging engineer and operators had been to the site many times in accordance with the customer’s production plan to guide and implement the packaging of the equipment. We communicated with customers’ construction, safety, operation and equipment coordination personnel on site to ensure correct packaging operations, so that the packaging can be completed on time and in a standardized manner.

The entire project was successfully completed in just over 10 days. The overall packaging solution takes into account transportation safety, efficiency and cost saving, which made the client very happy.

Solid wood pallets, solid wood strips, shrink wrap, rainproof cloth, desiccant, anti-rust paper, rubber, etc.

Read more

Save the warehouse cost Packaging materials can take up a lot of storage space and keeping packaging in stock involves various costs. This is why

As a packaging expert company we are proud to offer our customers a so called “On-site Packing”. This service is a much appreciated service where

Boxon has rich experiences in packaging and professional packaging engineering team. Our packaging engineers customize suitable and cost-saving packaging solutions based on your real situations.